- Applications

- Applications at factories

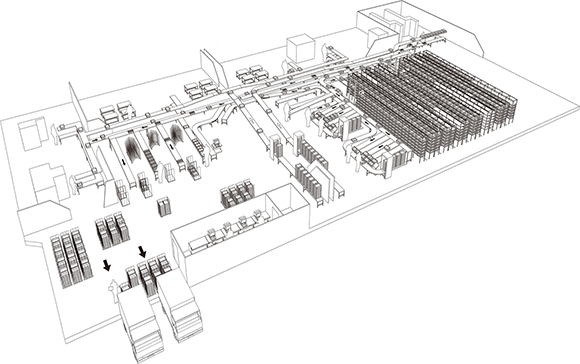

Processed food plant

- Transfer system

- AS/RS

Barcode-based management of ingredients.

Non-stop distribution with zero inventory.

Overview

A fresh vegetables processing plant. The materials handling system using conveyors and an AS/RS results in minimum storage of raw materials. Barcodes are used for total management of logistics from inbound to outbound. First-in/first-served inventory management is in place.

System benefits

- Trays holding ingredients are managed using barcodes.

- Zero inventory of ingredients is accomplished by means of the first-in, first-out system using an automated warehouse.

- All transport at the site, up to store-specific picking and sorting, is automated with conveyors, completely eliminating the use of dollies for transport.

- A two-level design with upper and lower levels has saved a significant amount of space.

-

Empty container stacker

-

Shipping terminal in the automated warehouse

-

VoiceFeedback from customer

Since our products have a short life, we can't allow picking or delivery mistakes. We developed our system with the goal of getting as close to zero mistakes as possible. Currently, both our information and material-handling systems are generating satisfactory results.

- Applications Navigation

-

- Processed food plant

- Rice-milling plant

- Brewery plant

- Food plant

- Beverage factory

- Snacks factory

- Vegetable factory

- Paper milling factory

- Pharmaceuticals distribution center

- Media items distribution center

- Books distribution center

- Daily commodities center

- Refrigerated food center

- International express cargo logistics center

- Apparel goods distribution center

- Supermarket distribution center

- E-commerce distribution center

- Sports goods distribution center

- Airport baggage handling system

- Agricultural products handling center