- Applications

- Applications at factories

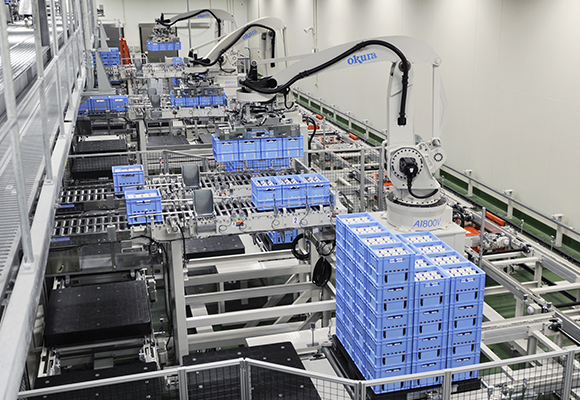

Beverage factory

- Robot

- Transfer system

- AS/RS

Achieving stable production with Okura materials handling equipment such as robot palletizes, AGVs, and an AS/RS.

Overview

Coffee and juice factory built by a leading dairy products manufacturer to aim at an effective supply of products to large-scaled supermarkets by using the most sophisticated materials handling system ranging from robots to AS/RS. Required manpower is also minimised.

System benefits

- Automatic process from the filling to the temporary storage

- Shortened lead time

- Stable supply of ordered products to big customers

-

Robot palletizing handling two different pallet positions at once

-

Empty containers transport line from washing process to casing process

-

AGV transfers completed pallets to the AS/RS with no human involvement

-

4,500 pallets at maximum are stored in AS/RS.

-

Robot de-palletizer de-palletizing stacked empty containers

VoiceFeedback from customer

Our aim is to handle orders from big customers smoothly from the new factory. The state-of-art materials handling equipment helps us achieve the aim.

- Applications Navigation

-

- Processed food plant

- Rice-milling plant

- Brewery plant

- Food plant

- Beverage factory

- Snacks factory

- Vegetable factory

- Paper milling factory

- Pharmaceuticals distribution center

- Media items distribution center

- Books distribution center

- Daily commodities center

- Refrigerated food center

- International express cargo logistics center

- Apparel goods distribution center

- Supermarket distribution center

- E-commerce distribution center

- Sports goods distribution center

- Airport baggage handling system

- Agricultural products handling center