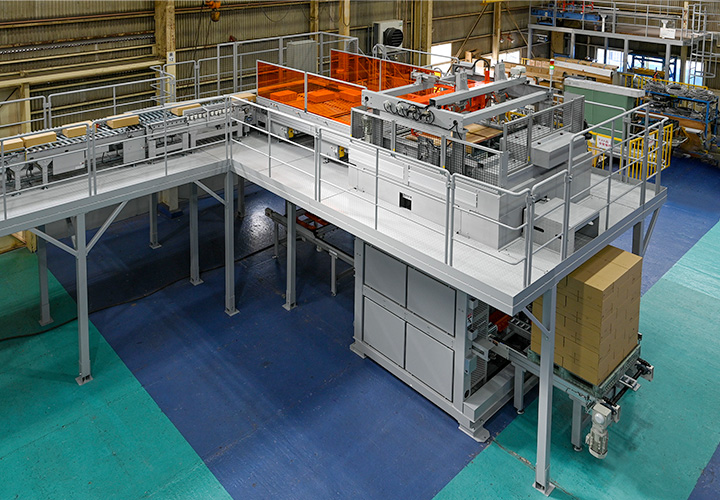

Palletizing equipment

PHC80LHigh-capacity case palletizer

The newly designed mechanism realizes in "shockless handling of products" and "a minimum foot space". Very smooth handling in the whole palletizing process achieves a high capacuty.

Features

- High capacity

80 cases can be palletized per minute.

- Gentle handling of the products with various kinds of "shockleess" mechanism.

Turning and diverting the products gently allows no damage to the products.

- Small foot space

Either straightforward layout or 90 degrees bent one are possible.

- Energy saving and low noise design

Almost no electricity is wasted due to simple machanism.

- Easier maintainability

Maintenance can be done easily thanks to simple unitized mechanism

- Easy operations

Easy operations can be done on the touch panel. The "OXPA-QM" Series enables patterns to be taught easily.

basic system architecuture

- Turn Conveyor

90 and 180 degrees turns without any shock to the products.

- Diverter

The skewed small plastic rollers divert the products gently.

- No.1 Layer Conveyor

The conveyor consisting of small plastic rollers accumulates products without any stopper.

Specifications

| Handled products | Wrap round cases(280W×410L) for dia 211 cans *8 cases×9 layers for cases with 350mm cans |

|---|---|

| Maximum capacity | MAX. 80cases/min. |

| Maximum palletizing height(mm) | 1,400mm(including a 140mm high pallet) |

| Maximum palletizing load | 800 ㎏(including a 50kg pallet) |

| Pallet dimensions(mm) | 900(W)×1,100(L)×140(H) |

*Processing capacity varies with factors such as palletizing pattern, number of stacking levels, and properties of the products being palletized.

- Palletizing equipment Navigation